In 2020, Winvic created its Civils and Infrastructure division and welcomed Rob Cook to the business to lead its ambitious private and public sector growth plans. Fast forward almost five years and we’re firmly established in the sector, delivering schemes that include significant highways works, bridges and structures, Rail Freight Terminals, and site wide infrastructure works.

Thanks to our expertise across the whole business and our ability to self-deliver key services – like the manufacturing and recycling of concrete – we’re in a unique position, and that’s why we continue to secure places on national and regional public sector Frameworks. We asked Rob, our Managing Director for Civils and Infrastructure, to give us his view on Winvic’s role in the industry and detail how we’re committed to driving carbon reductions, adopting innovative product solutions, and delivering a positive experience for stakeholders and local communities.

It’s hard to believe that in a few short months I will be celebrating five years at Winvic, and I couldn’t be prouder of the growth our Civils and Infrastructure team has achieved in that time. In 2020, all of our projects were for private sector clients, but today, we have places on five public sector Frameworks, two of which have been announced in the last few weeks.

The Eastern Highways Alliance Framework (EHF4) has appointed Winvic across three Lots to undertake a comprehensive set of schemes for 11 local authorities. Works will range from highway improvements, bridge and structural works, subways, culverts and retaining walls, through to town centre enhancements, drainage systems, canal works, and waste management facilities. We’ll also be delivering similar projects under six different Lots on the NEPO Framework, meeting the needs of 12 North East local authorities.

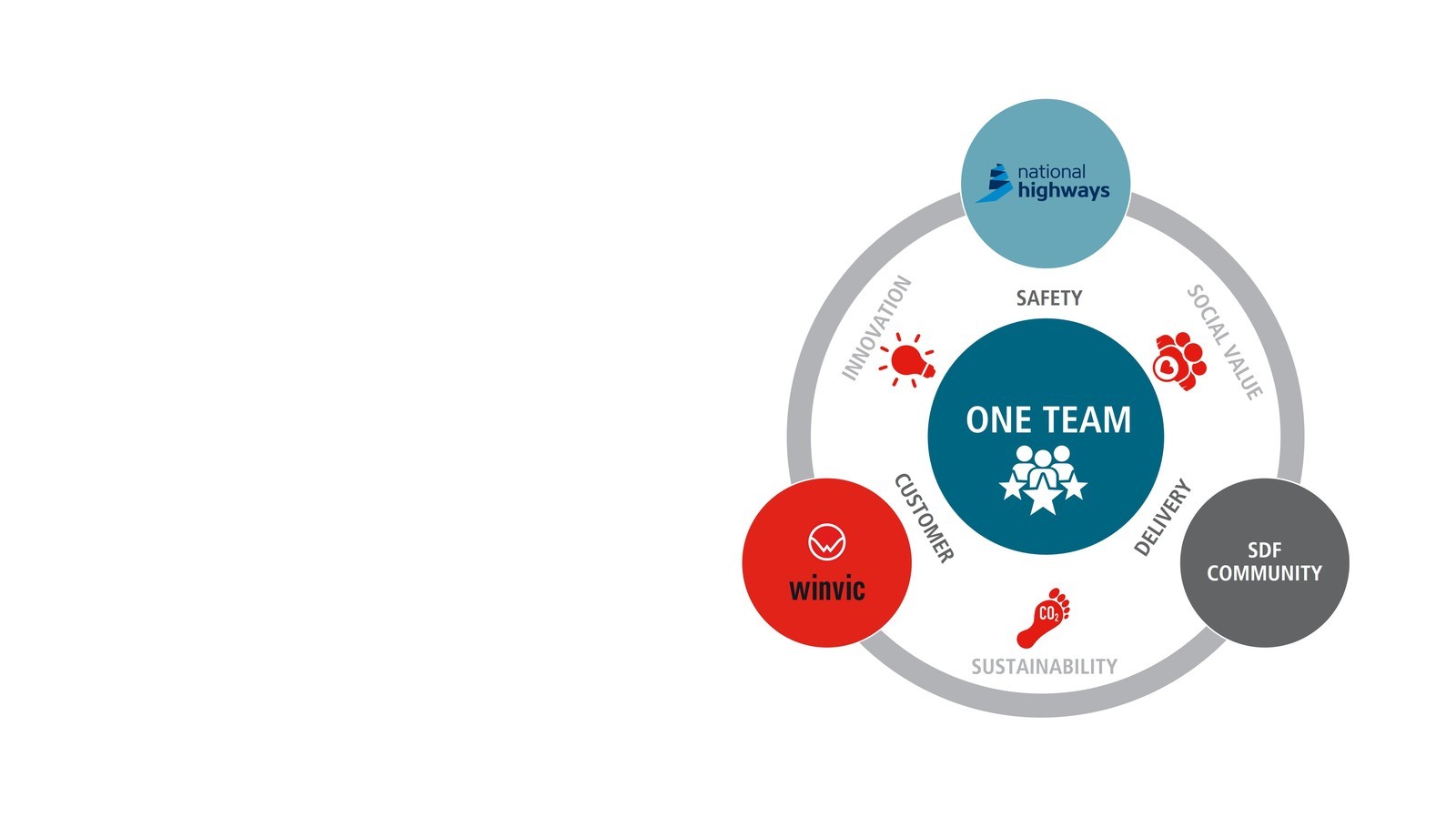

It’s safe to say that Winvic is firmly established in the Civils and Infrastructure space, with a strong reputation as a trusted public sector contractor. This success is driven by the depth of experience across the whole team, particularly when it comes to areas such as safety, innovation, social value, and sustainability. Not only are we able to apply our best practice learnings from over 20 years from the private sector, but we are also passionate about sharing our knowledge and thirst for improvement with clients and other public sector contractors, so we can collaboratively – and continually – help raise the bar throughout the UK.

2025 is going to be another busy and exciting year, and with our robust structure, experienced professionals and presence across the UK, we’re in prime position to effect continuity while upholding the high standards we are known for.

Investing in teams and partner companies for consistent and certain delivery

Ensuring stability in project planning, materials, plant, and workforce allocation is essential for consistent delivery of high-quality infrastructure through Frameworks. That’s why we’re committed to investing in local teams and building strong relationships with clients, supply chain partners and other stakeholders to be able to execute projects as effectively as possible. Keeping our workforce local ensures that we bring regional expertise and a deep understanding of the unique challenges that each area faces, plus those individuals have a vested and personal interest in the quality of work being delivered.

Our people are at the heart of our business, so it’s important that our approach benefits everyone. Having a steady pipeline of projects through Framework contracts enables us to provide long-term job security for our employees and subcontractors.

As well as guaranteeing an experienced and available workforce, Winvic can also offer programme certainty to clients through its ability to self-deliver key services. We have two partner companies within the Winvic Group; Sitecrete – a dedicated manufacturer and supplier of ready-mix concrete – and Premier Plant – a provider of the art plant, machinery, and surveying equipment. These partnerships mean we can quickly implement up-to-the-minute technologies and spearhead industry innovation.

Deploying mobile concrete batching plants and having full visibility over the machinery utilised allows us to enhance efficiency, have greater quality control and reduce environmental impacts. The benefit of utilising Sitecrete, for example, goes beyond our ability to be precise with our concrete mixes and reduce deliveries, waste and carbon. We can undertake highways reconstruction projects with a focus on recycling concrete that has reached its end of life. Instead of discarding old concrete, we process it through a batching plant and repurpose it as a sub-base layer for new roads, reinforcing our commitment to sustainable construction practices.

Innovative thinking in highways construction

Of course, being able to self-deliver in this way means that we are masters when it comes to research and development. I strongly believe that innovation is key to the future of road construction, and we need to remain flexible in embracing new materials and technologies. For example, warm mix asphalt, which requires less energy to produce than traditional hot mix asphalt, is improving efficiency while reducing the environmental impact.

Concrete technology has also made significant strides. For example, with self-healing concrete, carbon-eating concrete and no-cement alternatives now emerging, we are always looking at ways of incorporating these innovations into our projects. Another great example that has not yet been widely adopted in the UK is reinforced plastic drainage pipes that have the potential to replace traditional concrete products.

Our in-house sustainability experts champion for the greater acceptance of such materials, as they offer significant benefits in terms of reduced carbon emissions as well as the ease, speed, and safety of installation.

Advancements like these could redefine how we construct and maintain roads in the years to come. However, one challenge is ensuring that new materials and products gain approval and not get tied up in lengthy technical governance processes. This was discussed at the recent roundtable that we hosted at the Chartered Institution of Highways and Transportation (CIHT), entitled ‘Decarbonising Infrastructure: Collaborative Strategies for Public Sector Success’ – which you can read in the January issue of Transportation Professional magazine. I’m pleased we’re seeing a shift towards more flexibility in trials and implementation of new materials, which is an important step in the continual improvement of project efficiency and sustainability.

Open communication, sharing best practice and collaborative partnerships are also key ingredients to success and that’s why we value having the opportunity to have a voice when working with bodies such as the Civil Engineering Contractors Association (CECA), CIHT, Local Council Roads Innovation Group (LCRIG), UK Green Building Council (UKGBC) and the cross-party Westminster Advisory Board of the Policy Liaison Group on Environmental, Social and Governance (PLG on ESG). Our expert team members are also actively involved in many National Highways collaborative working groups, contributing their knowledge to drive industry-wide improvements.

Bridging the gap between local and national, public and private

While Winvic’s Civils and Infrastructure sector was officially formed in 2020 with my arrival as sector director, the company has been delivering infrastructure works as part of end-to-end projects since its inception. Winvic is also leading the industry when it comes to carbon reduction – particularly in building industrial facilities and distribution parks – we’re renowned for our commitment to utilising innovative products, materials and construction methods, and our in-house social value team is hailed as one of the industry’s best. When you combine these strengths, it’s easy to see why we have a lot to offer the public sector.

One area I’m particularly passionate about is improving the safety of diversion routes and implementing effective traffic calming measures during highways works. For example, working to minimise rat-running through small villages. We’re in a fantastic position to add value in this area due to our appointment on the National Highways Scheme Delivery Framework (SDF) as well as multiple local authority frameworks. And we bring an added layer of insight due to our delivery of large industrial schemes, which often have S278 works highways improvement elements, and impact the local road network.

Our collaborative approach means we can play an active role in finding design solutions that work for all stakeholders, we can minimise disruption for road users and communities and ensure projects are executed smoothly. By actively participating in regional engagement meetings, we can provide insights on traffic management and community impact mitigation strategies.

Putting customers and communities first

We’re proud of a lot here at Winvic and our work to ensure a positive experience for stakeholders and creating lasting benefits for local communities is regarded very highly in the industry. Our dedicated customer and stakeholder and social value teams work with clients, local authorities, employment and skills intermediaries, education providers and community groups to identify the needs of local people, and I have to say they have achieved some outstanding results. Page 12 of our latest issue of Winvic Word showcases some of this work, where you’ll find details of numerous projects, innovations and partnerships.

After being selected as a finalist in three categories at the National Highways Industry Awards: ‘Delivering Social Value – M62 Ouse Bridge Project’, ‘Customer-Focused Team of the Year – Winvic’s ‘Doing It Right’ Ethos’ and ‘Home Safe and Well Champion of the Year – Millie Nimmo, Doing It Right Putting People to Work campaign’, I proudly watched our team walk away with two trophies. A testament to our commitment to a safety-first approach, social value, and customer excellence.

Embracing our strategic advantage for 2025

As we navigate the evolving landscape of road construction and maintenance, my focus remains on sustainability, innovation, and collaboration. Our strategic advantage is broad, but it’s the strong relationships that we have built with clients, our ability to self-deliver and our experience of working in regions such as the Midlands, North East and East Anglia that stand us in good stead for our future growth. Our expert team members – across the whole business – ensure there’s nothing we can’t deliver in the civils and infrastructure sector. If we look at highways schemes alone, we’re experienced in delivering complex junction reconfigurations and brand-new roads, stripping end-of-life concrete roads and rebuilding them, prolonging concrete roads with a saw cut and sealed asphalt overlay and everything in between. Just have a look at some of our case studies, such as the concrete overlay to junctions 52 to 55 of the A14 under the SDF, or the resurfacing and junction improvement works to Newland, Lincoln as part of the Lincolnshire County Council Highways Framework.

By embracing new technologies and materials and fostering partnerships between the public and private sectors, we can build infrastructure that meets both current and future demands. As the industry evolves, I’m excited to see Winvic leading the way, ensuring our roads are built to last while leaving a lasting positive legacy.

Share

Share

Repost

Repost

LinkedIn

LinkedIn

Email

Email